Battery Energy Storage System (BESS) technology is revolutionising the way the Commercial & Industrial businesses store and manage their renewable energy. It plays a crucial role in renewable integration, grid stability and overall energy efficiency. However, with this rapid growth comes the need to ensure these systems are safe, reliable and equipped with robust fire safety measures.

Our commitment to fire safety here at Wattstor goes beyond compliance; it’s about installing energy storage solutions that protect your investment, infrastructure and peace of mind. Through rigorous testing, advanced system design and cutting-edge fire suppression technologies, we ensure our solutions set the highest standard in the industry for safety and performance.

Understanding BESS fire safety risks

To understand how best a solution is aligned to protect your investment, you first have to understand the inherent risks that come with battery energy storage technologies.

Thermal runaway

Thermal runaway occurs when a battery cell overheats, leading to a chain reaction that can cause adjacent cells to also overheat, resulting in a fire safety risk. Factors such as overcharging, excessive heat or physical damage can enhance this too.

Electrical faults

Electrical issues such as short circuits, overcharging, or exceeding voltage limits during charge or discharge can cause significant overheating. This overheating can break down the battery’s electrolytes and in turn be a fire safety risk.

Mechanical abuse

Physical impacts such as punctures, vibrations or crush damage, can compromise the structural integrity of batteries. This damage can expose internal components that increase the fire safety risk.

External Factors

Environmental conditions such as exposure to high temperatures or poor ventilation can exacerbate the fire safety risk by creating conditions conducive to thermal runaway. Proper site planning and installation practices, including adequate spacing and protective barriers, are essential to minimise these risks.

Mitigating BESS fire safety risks

Ensuring the safety of BESS requires a multi-layered approach that involves choosing safer battery chemistries at source, using smart Energy Management Systems (EMS), and robust fire detection and suppression measures. Here’s an overview of the key components of BESS fire safety and how Wattstor integrates these elements into their systems:

Battery chemistry

The choice of battery chemistry significantly impacts the fire safety profile of a BESS. Wattstor uses Lithium Iron Phosphate (LiFePO4) batteries, which are known for their enhanced safety characteristics compared to traditional lithium-ion batteries.

LiFePO4 batteries offer a lower risk of thermal runaway, increased thermal stability, and are less prone to catching fire or exploding under high temperatures or overcharging conditions. These batteries have undergone rigorous testing, including the UL9540A standard, which demonstrated their resistance to fire propagation and absence of external flaming or explosive discharges during thermal events.

Battery Management System (BMS)

The Battery Management System (BMS) is a critical component that oversees the health and safety of the battery modules. The BMS continuously monitors key parameters, such as cell voltage, temperature, and state of charge, to ensure the safe operation of the batteries.

In the event of overheating or any anomaly, the BMS can automatically isolate the affected battery module, preventing further escalation and minimising the risk of fire. This system acts as the first line of defence, protecting against conditions that could lead to thermal runaway.

Master Battery Management System (MBMS)

The Master Battery Management System (MBMS) extends the protective capabilities of the BMS by coordinating safety protocols across multiple battery modules within a larger BESS installation. The MBMS collects and analyses data from individual BMS units, ensuring system-wide safety and optimised performance. By managing the collective operation of the entire BESS, the MBMS enhances overall reliability and prevents cascading failures that could lead to dangerous fire events.

Fire detection and suppression systems

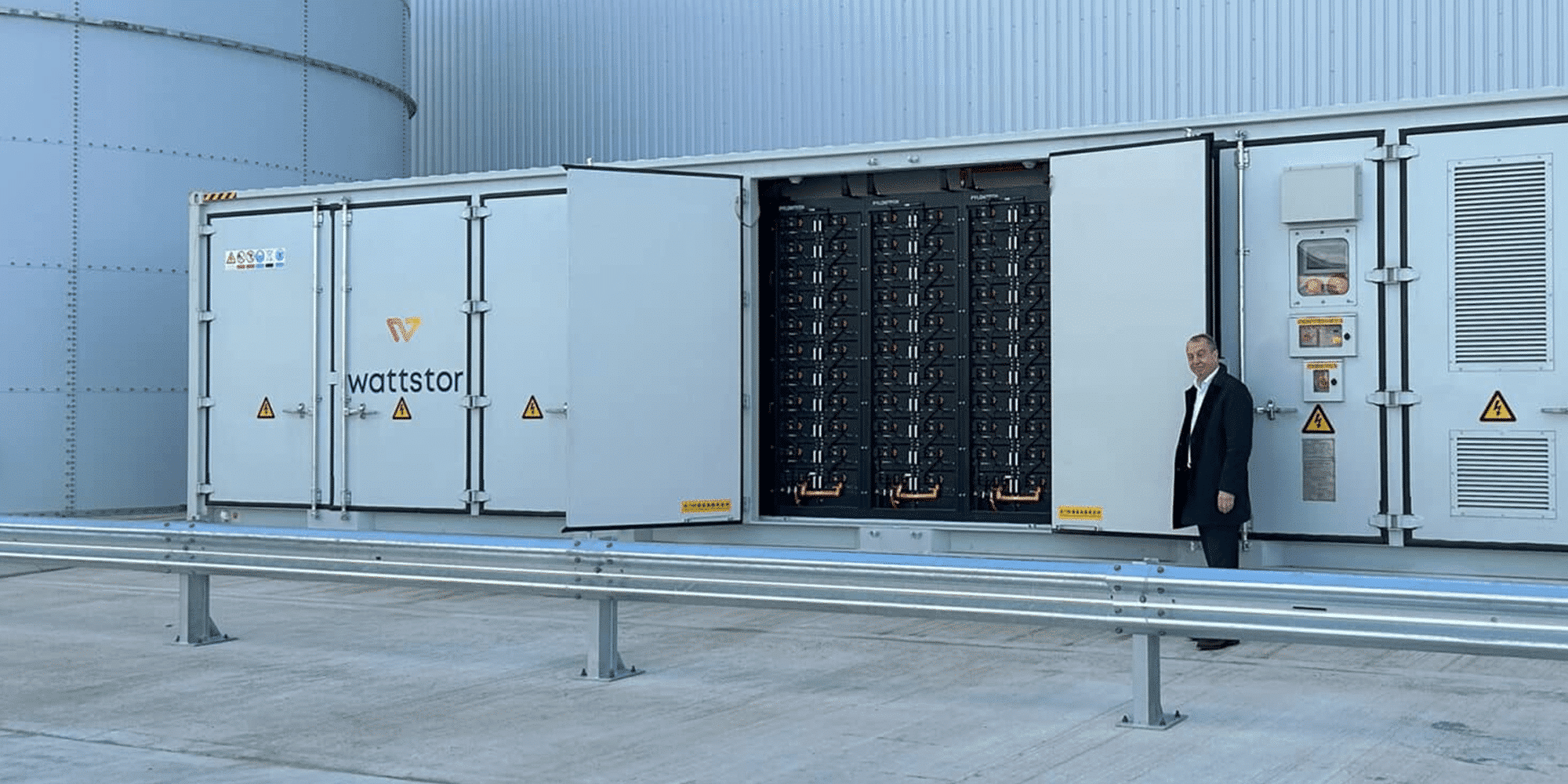

Effective fire detection and suppression systems are essential for mitigating fire risks within BESS installations. Each containerized BESS unit in our solutions is equipped with an integrated fire suppression system designed to detect, shut down, and extinguish fires quickly.

These systems include advanced sensors that monitor smoke, heat, and gas emissions, providing early warnings that allow for prompt response and control of potential fire incidents. The fire suppression agents used are specifically chosen for their effectiveness in electrical environments, non-conductive properties, and minimal environmental impact, offering a clean and efficient means of fire suppression without damaging sensitive equipment.

Proactive fire risk assessment

Identifying potential fire hazards early and implementing robust safety measures can significantly reduce the likelihood of fire incidents. We prioritise safety by conducting thorough site-specific risk assessments, strategically positioning units, and maintaining a rigorous schedule of inspections and maintenance.

Site-specific risk assessments

Conducting a site-specific risk assessment is an important first step in identifying potential fire hazards associated with BESS installations. This process involves evaluating the unique conditions of each site, such as proximity to combustible materials, environmental factors, and the layout of the installation.

By engaging with fire safety consultants, insurance providers, and local authorities, the Wattstor team ensures that each installation is tailored to meet the specific safety requirements of the location, enhancing overall resilience against fire incidents.

Strategies for safely positioning BESS units

We emphasise the placement of BESS units at safe distances from buildings, flammable materials and other critical infrastructure. This separation reduces the risk of fire spread. It also provides emergency responders with clear access to the units in case of an incident.

Key considerations include maintaining safe distances from vegetation, flammable liquids and overhead utilities that could pose additional risks.

Regular maintenance and inspections

Regular maintenance and inspections are fundamental to keeping BESS systems safe and compliant with industry standards. At Wattstor, we implement a structured maintenance schedule that includes frequent checks of the battery modules, fire suppression systems and overall structural integrity of the containers.

These inspections help detect early signs of wear, electrical faults, or potential hazards. Addressing them promptly prevents issues that could otherwise lead to fire.

Our maintenance protocols are aligned with manufacturer guidelines and industry best practices, ensuring that all components function optimally. This proactive maintenance approach includes testing fire detection systems and verifying the effectiveness of suppression agents. It also ensures that HVAC systems maintain the correct operating temperatures within the BESS units.

We are committed to delivering BESS solutions that set the standard for safety, reliability, and innovation. Our use of LiFePO4 batteries, integrated fire suppression with fire-resistant container design, and proactive maintenance ensure our systems are not just efficient but also secure. We don’t just meet fire safety standards. We aim to exceed them, providing our customers with the confidence that their energy storage is in safe hands.

With our continued focus on safety and innovation, we lead the way in developing BESS solutions that protect your investment. At the same time, we support a safer and more sustainable energy future.

Speak to an energy storage expert today

Know someone who'd be interested in this? Why not share it: