Wattstor is helping the UK’s largest independent pharmaceutical distributor to reach net zero.

| End user | Mawdsleys |

|---|---|

| Industry | Pharmaceutical distributor, logistics |

| Location | Doncaster, UK |

| Assets on site | Podium EMS / Wattstor BESS / DC coupled PV |

| Battery (BESS) | 750 kW / 2,500 kWh |

| Time of delivery | 5 months |

The Challenge

Mawdsleys is the UK’s largest independent pharmaceutical distributor with a large fleet of vehicles and multiple sites across the country. When planning the construction of a new temperature-controlled flagship warehouse, their aim was to generate as much (if not more) electricity as they consume. This was to be achieved by maximizing the solar panels installed on the roof.

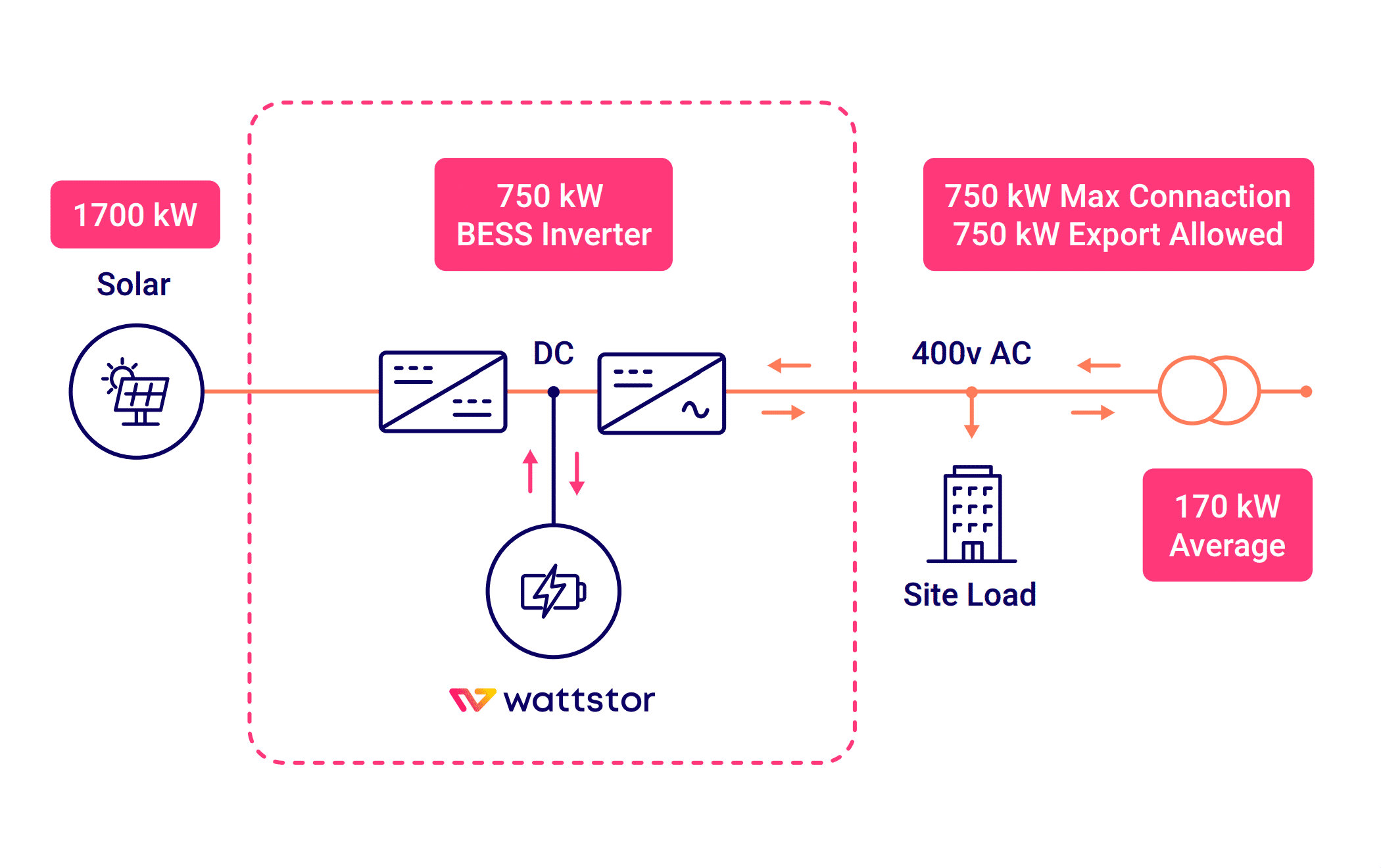

The warehouse’s projected demand was an average of 170 kilowatts per hour, which equates to an annual consumption of 1.5 gigawatt hours (GWh). To generate this amount of electricity, a 1700-kilowatt solar system would be needed on the roof.

However, the local distribution network operator (DNO) responsible for the grid would only allow them to connect 750 kilowatts of their own electricity generation, which means they could only generate 40% of the target value themselves.

The Wattstor solution

We used our DC coupled battery solution to maximize the size of Mawdlsey’s solar installation. This system decouples the sizing of the installed solar project from the sizing of the connection to the AC generation. By using batteries – which like the solar panels are DC devices – we can control the distribution of the solar generation coming from the roof and decide when it should be converted to 400V AC to supply the load on the Mawdsleys site and how much should be exported/sold to the local grid.

Mawdsley’s DC-coupled solution

For the Mawdsleys, this meant connecting a 2500 kWh battery to the solar system via a “DC/DC converter”. This is a power electronic system from Wattstor that throttles the flow of energy from the solar panels to the grid. It allows as much direct current (DC) as possible to flow from the solar modules into the converter, but also controls how much flows out again on the other side. The Wattstor system decides how much electricity flows into the battery and how much into the grid.

With normal site use, the system will deliver an average output of 170 kW. Initially, the company will export around 25% of the annual solar production. As the Mawdsleys expand their site and add e-trucks in the coming years, they can rely on this 25% solar surplus to support load growth.

Kevin Ball and Stephan Marty explain the work to install the batteries to Ed Miliband, the Minister for Energy and Climate Change

Introducing the Podium

We optimize all of this with our energy management system (EMS), Podium. Our EMS, which predicts the total output of the solar installation, the load on site and the forward market electricity price a day in advance, means we maximize the value of each kW of solar production every day. With this solution – by installing 10 times the amount of solar kW compared to their average kW electricity demand – Mawdsley has achieved their goal of becoming net-zero. What’s more, they can expect a “net zero” energy bill at the end of each year.

Mawdsley‘s Solar Battery Optimization Project – Wattstor is helping the UK’s largest independent pharmaceutical distributor achieve net zero.

10x

solar installed

means “net zero” energy bills at the end of each year

25%

Solar production

Surplus made available to support future load growth

Up next...

Support for the rollout of multi-site EV charging stations - National Highways

Contact us

If your commercial energy bills are too high but you have plenty of roof space, we could help you cut costs and carbon. Tell us more below

Contact us

If your commercial energy bills are too high but you have plenty of roof space, we could help you cut costs and carbon. Tell us more below

- +44 (0) 20 3868 5555

- [email protected]

- Wattstor Ltd, 21 Ironmonger Lane, London EC2V 8EY